Are Today’s EVs Truly Green?

EVs have shown promise globally and it’s no different for India. The Indian EV industry has witnessed dramatic growth over the last three years with a CAGR of 60% from 2019 to 2022 (as per Vahan Portal for battery operated vehicles). A total of 0.32 million EV vehicles were sold across the country in 2021 alone which was the highest in the history of Indian EV industry.

Shri Nitin Jairam Gadkari, the Minister of Road Transport and Highways of India, has projected a target of deploying 3 crores EVs by 2024 and the costs of EVs would match the cost of ICE (Internal Combustion Engine) vehicles. India will become the third largest automobile industry across the globe by 2030 as we meet these targets.

Government bodies like NITI Aayog have introduced policies aiming for 100% electrification by the end of 2030. This increase in affinity toward EV vehicles can be justified by their eco-friendly nature and the consistent rise in fuel prices.

Nevertheless, there are plenty of speculations around the sustainability aspect of EV adoption. Are EVs serving the purpose of fighting climate change? Are EVs truly green?

But before we answer these questions, let’s understand if we are measuring the right metrics.

Are we measuring the right metrics?

To understand this, we need to dive into the concept of measurable metrics relevant to EVs and the process of manufacturing. First things first, let’s talk about a few crucial terms associated with EV manufacturing.

The energy mix is the combination of different energy sources like thermal, solar, wind, fossil fuels, etc. used to meet the energy needs in a geographic region. Today, India has an energy mix of 56.7% coal and the remaining 43.3% accounts for oil and renewable sources like solar, wind, hydro, etc.

Embodied carbon emissions are the total amount of carbon emitted during the manufacturing and production stages of an EV. The main contributor to these emissions is the battery manufactured for EVs which accounts for >50% (as of today) of the total embodied emissions. The gCO2/km is the functional unit used to calculate the carbon emissions released per kilometer.

When it comes to measuring the metrics associated with the EV ecosystem, both financial and sustainability metrics must be taken into consideration. While the financial metrics (INR/km) remain the primary measurement metric, it is equally crucial to track the sustainability metrics (gCO2/km).

Sustainability metrics shouldn’t only include the operational emissions (emissions after the EV hits the road), but also the embodied emissions that leave a larger impact on the environment than ever anticipated. Embodied emissions are often overlooked by the end consumers due to a lack of knowledge and awareness. Mostly, the performance of EVs is measured based on their low operational costs (INR/km) and emissions and zero tailpipe emissions after the vehicle hits the road.

Furthermore, we should also look at other essential metrics to calculate the performance of EVs, such as the Total Cost of Ownership (TCO) through the life of the vehicle and the battery life. The total cost of ownership is an overall estimate of the total expense incurred right from the production, purchase, to deployment and entire lifecycle of the electric vehicle.

When we start measuring the right parameters, it broadens our scope of understanding the EV ecosystem from different perspectives.

How is the change in perspective going to affect the current scenario?

Of the many myths around EV adoption, one is net-zero emissions. When a person buys an electric vehicle, the first thought that comes to mind is taking a step toward fighting climate change. While this is partially true, there’s another side of the story – the energy and resources that go into the production process.

The life cycle of an EV goes beyond its total runtime. It starts with the battery manufacturing process and continues through the EV deployment and its operational life. Battery manufacturing lead to high carbon footprints, which takes years to break even with ICE (Internal Combustion Engine) vehicles. The raw materials used, such as lithium, copper, nickel, and manganese emit toxic emissions.

The gaps are not limited to the amount of carbon footprints created during the battery manufacturing process. The energy mix in the national electrical grid is also a responsible factor as the majority of the energy resources are non-green (thermal/coal).

Another significant point of consideration is the life cycle of a battery. The battery life is determined by the cell technology and the # cycles utilized in the use phase. With higher utilization in commercial vehicles, a battery replacement is bound to come that not only increases the Total Cost of Ownership (TCO) through the life of the vehicle, but also emissions accrued to battery manufacturing.

So, buying an EV doesn’t reflect a positive ecological impact instantly, neither does it breaks even with an ICE vehicle. It takes years to reach a parity point after the vehicle has hit the road, Parity point is achieved when the total emissions reduced during the use phase of the vehicle is equivalent to its total embodied emissions.

Now the question is, how do we bridge these gaps? According to sustainability experts, developing clean energy is a responsible step for making EVs greener. Scientists and industry experts are also looking for more efficient battery technologies that ensure lower embodied emissions and a longer life cycle.

When do EVs become truly green?

Although the operational costs and emissions of EVs are lower than their ICE counterparts, it is essential that the lifetime emissions of electric vehicles break even with a combustion engine vehicle. It happens when an EV reaches the parity point.

After an EV customer reaches the parity point, the vehicle turns truly green. The time it takes to achieve the parity point is called green payback years.

How long does it take to reach the parity point? Let’s evaluate the runtime across the life of the vehicle to understand this.

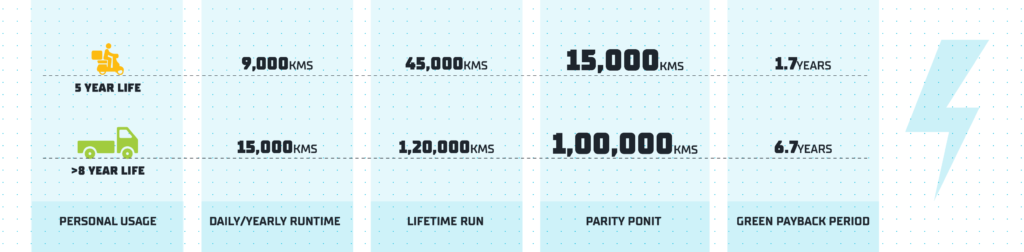

Typically, a personal user drives for >15kms a day, ~40,000kms over a 5-year life (smaller platforms like 2W), and 80,000-1Lkms over an 8-10 year life (heavier platforms like 4W). Bigger the battery pack, the higher the embodied emissions difference and the higher the parity point and payback years. A simple assessment portrays the following:

The above table shows that a 2W must drive for 15,000kms or >1.5 years to unlock a green parity point, whereas a 4W must drive ~1,00,000kms or >6.5 years to achieve a green parity point. These numbers vary in the case of commercial EVs due to the higher runtime (>100kms a day), reducing the payback years. However, a lower payback period also indicates faster battery degradation and replacement, which ultimately increases the TCO for the consumer, both economically and environmentally.

So, does the battery type used in the EVs lasts for 5 years to reach the parity point? Is there a permanent solution to these new challenges in the EV ecosystem?

Log9 - Pioneering responsible batteries

To resolve the challenges of mass EV adoption and with an intention to ensure electric vehicles truly become a greener alternative to ICE vehicles, Log9 has come up with its indigenous battery technology.

Log9 batteries, having a high cycle life, allows utilization of each battery for multiple commercial EV applications (>3, minimum 15 years), whereas traditional batteries can power multiple units (~2-3) for just 1 commercial EV application. The longer life cycle of batteries (>10 years) eliminates the need for battery replacement every 3-4 years, ultimately cutting down on the TCO.

While a conventional battery ends up in the landfill after 3-4 years, Log9 batteries continues to deliver high power, performance, and peace of mind to the end users. Through the life of an EV vehicle powered by Log9 batteries, it records a notable reduction in the carbon footprints, creating a positive impact on the environment.

The key to unlocking the true decarbonization potential of the transportation industry and the logistics segment lies in advancements in cell chemistry and material choices that deliver capabilities suited for implementation. Battery technology selection for EV manufacturers will be a significant driver in supplying EVs for e-commerce and logistics service providers in the future.

Rajat Singh

Sustainability & Stationary Energy Storage - Founders Office